Product introduction: Perform multi-parameter polarization curve test of proton exchange membrane fuel cell, complete performance evaluation, durability control strategy research and other work

1, 0V start, full current with load

2, reverse pole with load, automatic back pressure

3, gas ratio 0-100%

4, high current 0 ~ 240A

5, Desktop structure

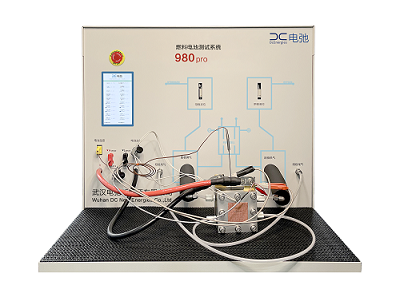

980Pro Fuel Cell test system

Product introduction: Perform multi-parameter polarization curve test of proton exchange membrane fuel cell, complete performance evaluation, durability control strategy research and other work

Main functions: fuel flow control and backpass measurement, fuel humidity control and backpass measurement, fuel temperature control and backpass measurement, internal resistance measurement, battery performance loading, multi-stage current range switching function, constant current, constant voltage, constant power load control mode, half battery electrical analysis function, concentration experiment, gas metering ratio test, poison test. It can meet the needs of diverse experiments.

Technical interpretation

A fuel cell is an electrochemical generator that converts chemical energy into electrical energy, and achieves the effect of continuous discharge by continuously adding fuel. Hydrogen energy has now gradually shifted from key technology research and development to the stage of industrial development.

Hydrogen advantage

① Hydrogen is from a wide range of sources and is not constrained by resources

② The catalyst platinum consumption is low, and the platinum resource recovery rate is very high, the latest overseas research can reduce the platinum consumption to 0.06g/kW (about 7.06g/ vehicle)

③ Carbon peak/carbon neutral, two-carbon strategy, green hydrogen production

④ Fuel cells are safer than lithium batteries, and there is no risk of spontaneous combustion and explosion under normal operation

980Pro product features

1, 0V start, full current with load

In general, during the overload test process, the fuel cell generally runs the battery for a period of time specified by the battery manufacturer, or until the battery voltage is reduced to a value specified by the battery manufacturer. If we require the electronic load to start the test from low voltage or 0V, we will face the problem of high current load due to "0V start".

The "0V start" fuel cell test system can avoid the above problems, and can help us to maximize the VI characteristics of the battery. The 980Pro solves this major pain point.

2, reverse pole with load, automatic back pressure

Back pressure is the pressure regulation of the air entering the fuel cell system to supply the appropriate state of air (oxygen) for the cathode of the fuel cell, which directly affects the performance and efficiency of the fuel cell. Too high or too low back pressure will lead to large fluctuations in gas flow, which will harm the fuel cell system.

The automatic back pressure is controlled by computer software, which can control the test value very fine, with very high precision, and can maintain the continuity and stability of the back pressure for a long time, without human intervention factors, and the experimental data is more reproducible and more convincing.

3, gas ratio 0-100%

In the fuel cell system, hydrogen is used as a fuel supply and oxygen is used as an oxidizer to participate in the reaction, improving the efficiency and stability of the fuel cell - the role of "gas ratio" is prominent.

Safety: Study the composition of the gas discharged from the fuel system and the composition, quantity ratio and characteristics of the gas discharged from the air system.

Economy: Hydrogen utilization affects the reduction of commercial costs of hydrogen fuel cells. The analysis and test of hydrogen per hour consumption rate, oxygen per hour consumption rate, and air supply per hour are studied to explore efficient and energy-saving fuel control strategies.

Durability: Too high or too low gas pressure and flow will cause overall fluctuations and affect battery life. Analytical testing helps detect the durability of the fuel cell.

4, high current 0 ~ 240A

5. Desktop structure

The desktop fuel cell test system is small, does not pick space, and is convenient for loading and handling. Electronic load design is moderate, can meet most of the experimental test needs, high cost performance

Hardware advantage

It can be started at 0V, corresponding to the low voltage and high current characteristics of the fuel cell.

High response speed: 100ms

High response mass flow controller

Ultra-wide stability control: 10,000:1 (0.01%-100% range) applied to the dynamic mixing of mixed gases

High precision: Standard accuracy ± (0.8% reading +0.2% full scale) High precision (optional) : ± (0.4% reading +0.2% full scale)

Ultra-wide stability control: 10,000:1 (0.01%-100% range)

High precision (optional, NIST traceable) : +/-0.125% full scale

Standard accuracy (NIST traceable) : +/-0.25% full scale

High stability back pressure controller (optional)

Various single battery clamps available

Wide selection of gas types: 98 preset selectable gases

NIST Traceable Calibration certificate

Software advantage

Fast data extraction speed of 5 points per second

Safety logic to ensure battery test stability

Check test conditions edit screen, fast programming

Data is displayed in real time, and key data is displayed separately

Historical data show comparison

Report generation and export function

Main technical index

1. Humidification method: bubble humidification

2. Humidification temperature range: room temperature ~90℃

3. Humidifying humidity range: 100% RH-@ Maximum flow (5L)

4. Anode gas flow control: up to 5 SLPM

5.Cathode gas flow control: up to 10 SLPM

6. Temperature control sensing form: T-type thermocouple

7. Safety protection maneuvering: remove the load, stop heating, nitrogen cleaning, stop fuel supply

8. Start protection items: over current protection, low voltage protection, communication failure protection, automatic nitrogen cleaning protection, temperature protection, abnormal water supply protection, humidifier level warning protection, insufficient intake pressure warning protection

9. One set of manual emergency stop switches

10. Dry and wet switching mode: automatic

11. Wet and dry switching channels: anode and cathode in two groups

12. Maximum power: 100W

13. Current range: 0~24A/0~240A Support for customization

14. Current setting resolution: 0.4~4mA

15. Voltage range: -0.7V~2V/-3.3V~10V

16. Voltage setting resolution: 0.05/0.25mV

Main technical index

1. Humidification method: bubble humidification

2. Humidification temperature range: room temperature ~90℃

3. Humidifying humidity range: 100% RH-@ Maximum flow (5L)

4. Anode gas flow control: up to 5 SLPM

5. Cathode gas flow control: up to 10 SLPM

6. Temperature control sensing form: T-type thermocouple

7. Safety protection maneuvering: remove the load, stop heating, nitrogen cleaning, stop fuel supply

8. Start protection items: over current protection, low voltage protection, communication failure protection, automatic nitrogen cleaning protection, temperature protection, abnormal water supply protection, humidifier level warning protection, insufficient intake pressure warning protection

9. One set of manual emergency stop switches

10. Dry and wet switching mode: automatic

11. Wet and dry switching channels: anode and cathode in two groups

12. Maximum power: 100W

13. Current range: 0~24A/0~240A Support for customization

14. Current setting resolution: 0.4~4mA

15. Voltage range: -0.7V~2V/-3.3V~10V

16. Voltage setting resolution: 0.05/0.25mV

If you are interested in our company's products, please fill out the form below and we will contact you as soon as possible based on your needs.